Plastic injection molding is one of the most versatile processes available, suitable for a wide range of product applications at, most often, a favorable price point. As with nearly any manufacturing process, however, there are other solutions that can be worth exploring for more specific needs. In the case of plastic injection molding, your needs may dictate that a reaction injection molding process can provide more favorable manufacturing properties and pricing than the standard plastic injection molding process.

If you aren’t familiar with the reaction injection molding process, we’ll take a closer look at it, including how it’s similar to — and different from — standard plastic injection molding. We’ll also look at the steps of reaction injection molding as opposed to plastic injection molding process steps — and how they play a part in your decision making.

Plastic Injection Molding vs. Reaction Injection Molding

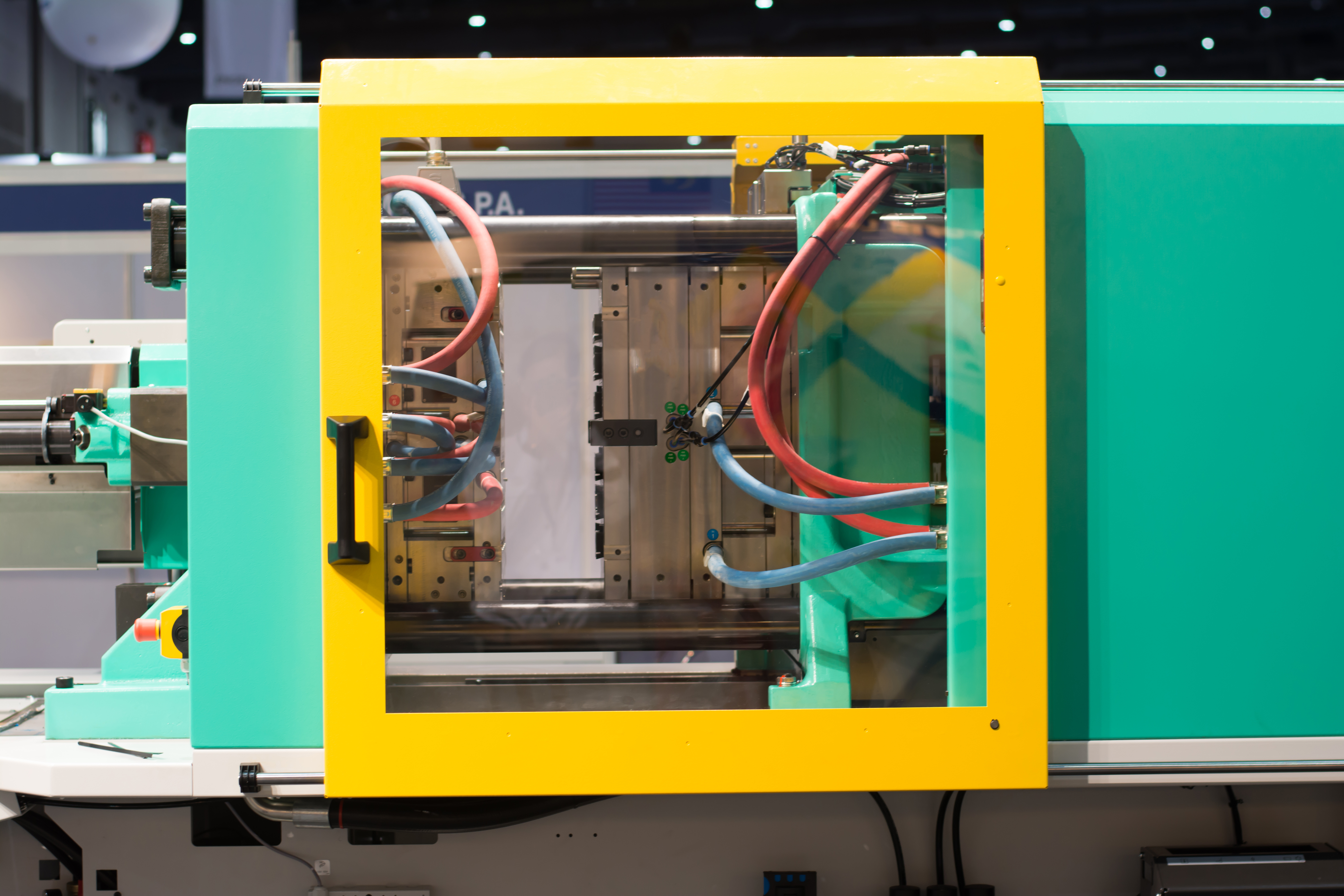

In plastic injection molding, as you’re likely aware, a plastic resin (often in the form of pellets) is heated to a melting point (which can differ by material). Once melted and homogenized into an injectable liquid form, the resin is fed through the injection molding machine and injected with pressure into the mold cavity or cavities via the mold sprue and runners. As pressure continues to be applied, the liquefied material fills the mold cavities and begins to cool. Once the mold is completely filled, the cooling process is often accelerated by applying an external cooling element to the mold. This is done so the resin re-assumes its original solid form and is then ejected from the mold once it has hardened to an acceptable point.

In reaction injection molding, the process is quite similar, with a few key differences. A different type of substrate material is used, called a thermoset material. Thermoset materials work in basically the opposite way as standard (or thermoplastic) resins, in that they are hardened by heating (or curing) instead of cooling. Reaction injection molding is also different in that, by nature, two base polymers are combined (as opposed to plastic injection molding, where materials can be combined, but it isn’t required). The two materials must be combined because they then cause a reaction that causes the material to fill the mold cavity via expansion. This is where the name “reaction injection molding” originates. Once the mold cavity is completely filled, it is heated. This causes the material to (irreversibly) harden and set.

In reaction injection molding, the key points to remember are that constant pressure is not necessarily needed to “pack” the mold. Because, the materials react and expand on their own (though pressure is still required to get the material into the mold); and that heating — not cooling — causes the material to harden and set.

What Are the Advantages of Reaction Injection Molding?

At a high level, reaction injection molding and plastic injection molding are still quite similar:

- • A mold is created with a “negative image” of the product or part to be made

- • The mold cavity is filled with a material

- • The material hardens in the shape of the mold (and the finished product) and is ejected for inspection, processing and packaging.

All true, but the processes are not identical — and reaction injection molding can yield advantages in certain scenarios. These include:

In standard plastic injection molding, design best practices (which are useful and often critical in acceptable rates of part quality) dictate a somewhat rigid design protocol. For instance, uniform wall thickness, or very gradual changes in thickness, are a benefit. Further, extremely thin walls can be difficult to produce with plastic injection molding. In addition, the thermoset materials used in reaction injection molding have a lower viscosity than the molten thermoplastics of plastic injection molding. Meaning, they can flow more freely into a mold and thus more easily fill difficult-to-reach areas that might be inadvisable for other processes.

In standard plastic injection molding, design best practices (which are useful and often critical in acceptable rates of part quality) dictate a somewhat rigid design protocol. For instance, uniform wall thickness, or very gradual changes in thickness, are a benefit. Further, extremely thin walls can be difficult to produce with plastic injection molding. In addition, the thermoset materials used in reaction injection molding have a lower viscosity than the molten thermoplastics of plastic injection molding. Meaning, they can flow more freely into a mold and thus more easily fill difficult-to-reach areas that might be inadvisable for other processes.

With reaction injection molding, different wall thicknesses are much easier to produce, without the gradual changes necessary in plastic injection molding. Thinner walls and somewhat more complex designs can also be more easily produced, due to the lower material viscosity. What’s more, very large parts are often advantageous to produce with reaction injection molding.

Lightweight parts. The materials used in reaction injection molding often lend themselves better to low-density, lightweight parts than standard plastic injection molding materials. For this reason, reaction injection molding is often used for automotive and aerospace components that must be large and strong, but lightweight.

Lower tooling costs. Molds for reaction injection molding can often be produced from softer and thus lower-cost metals such as aluminum, as opposed to high-grade tool steel. Because, the heating required is less extreme, and there is less of a fluctuation between the heating and cooling temperatures. Thus, reaction injection molding can often be an ideal choice for low-volume or prototype production runs, since the major capital expenditure for a tool steel mold is not required. In addition, it can be beneficial to work out the math on reaction injection molding tooling versus plastic injection molding tooling for extremely high volume runs. Reason being, the lower tooling cost can play to your advantage in those cases, as well.

Lower machine costs. Reaction injection molding is, in general, a less “intensive” process than plastic injection molding: the packing and holding stage will likely not be required; lower clamping force is necessary for the mold when using the thermoset instead of the thermoplastic materials; and mold and machine temperatures are less extreme. For these reasons, overall costs when using reaction injection molding can be lower — whether you are a molding facility or an entrepreneur looking to contract a manufacturing service provider.

At RevPart, we’re happy to answer any questions you may have about design, process and production choices. Our experience and expertise in the field mean that we’re well-equipped to provide our honest and informed take on just about any questions you may have. Contact us today to talk about your design concept or production needs.