Step 1: Design your part. Step 2: Prototype and iterate on it to optimize your design. Step 3: Move forward to production. Wouldn’t it be nice if product development were that easy? By now, you probably have a pretty good idea that it’s not. There are a few more steps (and sub-steps, and repeated steps, and so on) and considerations of the plastic injection molding process to factor in, which is likely why you’re here. Material selection for injection molding is a primary consideration among these.

While the process of “material selection” certainly merits a step of its own, in many ways, it’s something that’s both affected by, and can have an impact on, most (if not all) other steps — and will definitely have an effect on the final step in development: production. The particulars of how you carry out your resin selection process are best defined by you and the way your development team works. In general, though, the earlier you start thinking about it, the better. Of course, it’s never a bad time to work toward a deeper understanding of the available materials and their properties.

Injection molding resins have a number of qualities that factor into their behavior, performance and ideal applications — both during production and in their end-use form. Since we’ll be covering the role that each of these qualities might play regarding requirements and aspects of the product design and function, let’s take a quick refresher of what they mean:

- • Durometer: Also referred to as the hardness of a material. When referencing durometer or material hardness, you’re talking about its ability to resist abrasion or indentation when acted on by an outside force. Durometer can be a consideration for cosmetic reasons — for example, in instances where material shouldn’t be able to be scuffed or scraped. Yet it’s also measured at a molecular level, which can be a factor in more high-precision applications.

- • Flexibility: Flexibility is a material’s ability to revert to its original shape after being bent, without breaking or shattering. Remember that a “hard” material according to durometer can also be very flexible, while a “soft” material might be more brittle and thus more subject to breakage. These first two material qualities are not interchangeable.

- • Temperature resistance: This refers to a material’s behavior in extreme temperature conditions, either hot or cold. Some materials may begin to weaken or even melt at higher temperatures (or, in the case of thermoset materials, to burn), or may become more brittle in extreme cold.

- • UV resistance: For outdoor applications, UV resistance is as important a factor as temperature resistance. UV resistance measures a material’s ability to retain its properties — strength, shape, appearance — when subject to direct sunlight.

The above factors all reference material properties in a resin’s final form. Nonetheless, different materials also have different properties during production, which can play a role in material selection. These include:

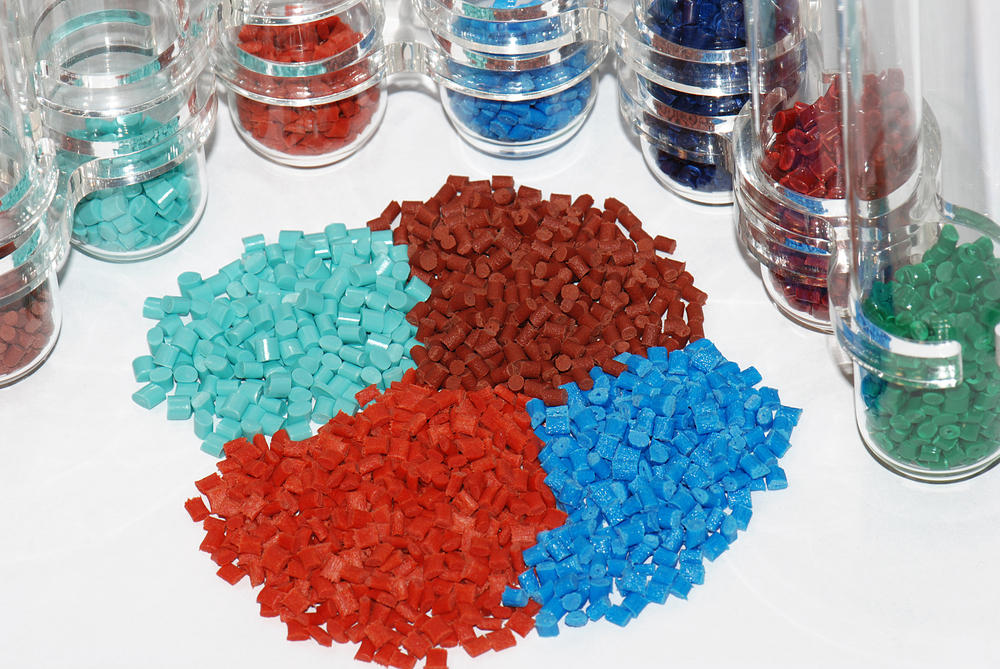

- • Melt temperature: The temperature required to change the solid resin pellets to a molten liquid for injection.

- • Viscosity: This property relates to the way a material will flow through a mold — the more viscous a material, the thicker it is in liquid form.

- • Melt profile: Different types of resins melt in different ways. Molecularly, resins fall into two categories: amorphous and semi-crystalline. The important takeaway from this distinction is that amorphous resins melt gradually as temperature increases over a certain melting point, whereas semi-crystalline resins melt completely once a certain melting point is reached. This variance can play an important role in production, which we’ll look at shortly.

While the above list provides an understanding of the types of material properties a resin might have, let’s look at some of the questions where they can provide answers.

What type of part is being manufactured? “Part type” can cover many qualities, for instance: Is it consumer-facing or something used primarily as a component of another product? Is its appearance important? In which industry is it being used? What is the size of the part — is it a large-scale piece or a small component?

Material selection is a key consideration for all of these, and more. For example, with consumer parts, a material that can be easily dyed, painted or surface-finished may be more desirable if aesthetics will be important. For aerospace components, temperature resistance may take priority.

How complex will production be? Again, production complexity can involve several factors: Is your part itself complex, with an intricate mold? Will your part be overmolded? Will more than one material be used? As you consider these questions, think about the following qualities discussed above:

- • Viscosity: For complex parts, lower viscosity may be preferential so that the material can more easily flow through the mold and fill the entire cavity.

- • Melt temperature: A lower melt temperature may also be useful for more complex parts, ensuring that the material remains in liquid form for a longer period as it flows into the mold cavity.

- • Melt profile: If multiple materials are being mixed in production, melt profile is a critical concern and should be considered alongside both the in-production and end-use properties of the material. If amorphous and semi-crystalline resins are mixed, they will not melt uniformly and thus are unlikely to be able to properly fill the mold.

- • Material interactions: For overmolded parts, be certain your material will not have any adverse chemical reactivity to the material around which the resin is being molded.

What is the intended use of the part? Will your part be used in high-impact applications? Be sure to consider both the hardness and flexibility of the material, confirming proper strength without risk of breakage or shattering. Harsh environments such as aerospace (mentioned above), as well as underwater or even uses in the space industry, also have major material implications — temperature suitability, UV resistance, chemical interaction and resistance, and more. Of course, more conventional uses such as children’s toys may also be considered a “harsh environment.” Thus, materials chosen for those applications should be more resistant to breakage and damage.

If you’re ready to choose a material for your project, or just want to know more about materials at an earlier stage of your product development, contact RevPart today.