Mold design and construction is a critical part of the injection molding process, and until somewhat recently, you didn’t have many options as to how you’d build your mold. Tool steel was (and remains) the most popular option, chosen for durability and machinability, and softer metals such as aluminum were sometimes used for specialized, shorter-run scenarios. The effort of creating a mold from a different material was viewed as not worth the investment, since the intensity of the injection molding process meant that molds made from other materials could only produce — at most — a few parts, if they worked at all. Different processes, like conventional machining, were thus seen as more cost-effective at such low quantities.

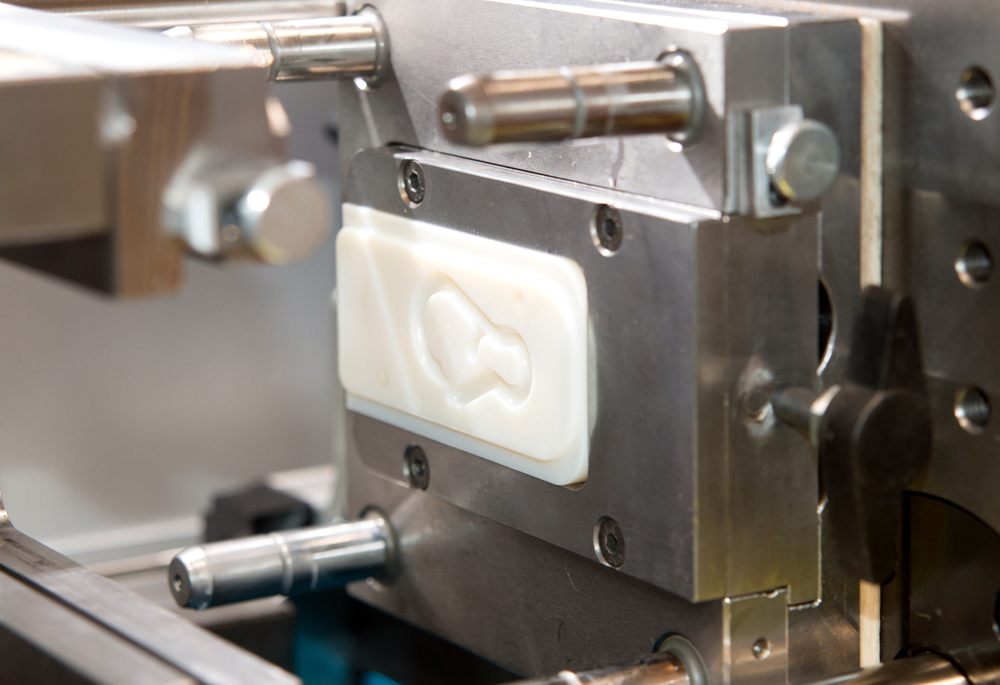

The widespread availability of 3D printing has changed that. With more and more material options, more process expertise, and more pushing of the boundaries previously adhered to in manufacturing, 3D printing molds has become an increasingly viable solution for certain injection molding applications.

By drawing on the primary benefits of 3D printing — namely, design flexibility and fast turnaround times — injection molding manufacturers have been able to create more innovative solutions, primarily for low- to medium-quantity production runs.

3D printing molds for plastic injection molds has made a significant impact on the injection molding industry, allowing the process of injection molding to be used in applications and quantities where it previously hadn’t been viewed as an option. At this point, let’s pause and compare four key characteristics of 3D printed molds as compared to standard tool steel molds, for a side-by-side view. Then, we’ll take a more in-depth look at the unique benefits that 3D printing molds can provide.

- Mold cost: 3D printing offers a major cost benefit for the production of the mold itself. Steel mold costs can run into the six figures, while 3D printed molds will typically only run to a small percentage of that.

- Turnaround time: The ease with which 3D printed parts can be created means that 3D printing has significant speed benefits over tool steel molds. Machining a steel mold is no simple task and can take weeks, while 3D printed molds can be delivered to your facility as quickly as a few days.

- Durability: Steel molds offer the clear-cut advantage here — 3D printed molds are most appropriate for lower production runs, and do not offer the lifespan of millions of cycles that steel molds do. For this reason, the benefits of 3D printing a mold should be weighed against the requirements of the project.

- Cost per part: This point can be considered a draw, depending entirely on the intended production run. Steel molds offer major benefits in cost per part at higher quantities, when the much higher initial investment is offset by the amount of parts that it’s able to produce. On the other hand, at quantities below several hundred, a 3D printed mold will most often be advantageous in this metric, with the lower initial investment providing benefits here. The math differs for every project, but the cost benefit for 3D printing usually maxes out around quantities of 500 parts.

Prior to the widespread use of 3D printing for plastic injection molds, those midlevel quantities in the hundreds of parts presented a real conundrum for entrepreneurs and manufacturers, where there was no clear-cut, cost-effective solution for production. This would often result in unnecessarily high production runs to lower the cost per part, or more time-consuming and expensive production methods such as conventional machining.

One more benefit to mention regarding how 3D printing molds has affected the industry is the ability to create cost-effective injection molded prototypes. Previously, it would have been almost impossible to justify the cost of an injection molded prototype using a steel mold, but with 3D printing, it’s achievable as a manageable investment. The benefit here is that the manufacturability of a product — its suitability for the process at hand — can be much more easily judged by creating a prototype using the production process. Without this benefit, manufacturability must be assessed by modeling and calculation, rather than observing the process itself.

How Can 3D Printed Molds Be Adapted for Higher-Run Projects?

The ability to be cost-effective up to runs of several hundred pieces means that 3D printed molds have plenty of applications already. However, there are several other ways in which these molds can be used and adapted that make them suitable for an even broader range of uses, and higher quantity runs. These include:

- • Hybrid 3D printed and aluminum molds: In this case, a 3D printed mold is fitted into an aluminum frame, giving it additional sturdiness and helping to prevent warping (and thus misshaping in both the interior and exterior of the mold). The theory behind this practice is that 3D printing can be used to create the unique part of the mold — the part that determines the shape of the part — and this can be fitted into a more durable, standardized frame for extended use. While this doesn’t change the fact that 3D printed material can only stand up to the superheated, molten plastic resin for so many cycles before it begins to break down, the additional sturdiness of the aluminum frame can extend the lifespan of the mold by several hundred cycles, bringing it close to 1,000 parts in most cases.

- • As mold inserts: Operating on a similar principle, 3D printed parts can be used to easily modify the interior shape of a steel or aluminum mold (thus changing the shape of the part produced). With the right mold design and product requirements, many configurations can be achieved using a steel mold template and different shapes and configurations of inserts. The key to success with this method is design, process control and planning.

The opportunities presented by 3D printing for injection molding mean that any molding service provider should have familiarity with the benefits and the right scenarios for use. At RevPart, we’re experts — contact us with any questions.