Standard lead times of weeks or months are often seen as a built-in and unassailable part of the injection molding production process. In both the prototyping and manufacturing stages, conventional wisdom says that tooling design, manufacturing and production are extremely time-consuming processes — with the price tag to match. These long lead times are not a mere inconvenience; they can and often do have very real effects on your product and your bottom line. Urethane molding is a readily available way to work with shorter lead times (and lower costs) and get your product to market faster, without sacrificing the quality or design of your product.

Before we look at exactly how urethane molding can reduce lead times and get your product to market faster, let’s examine the “why” more closely. As we said above, long lead times are more than a mere inconvenience and are in need of a more effective solution than “patience” or “it is what it is.” Why? With long lead times for prototyping and production, you may encounter issues such as:

- Higher costs for time-consuming design and production processes

- Longer time to market, affecting your bottom line through your ability to earn revenue

- The temptation to cut corners or skip steps, such as prototype iterations, in order to counteract long lead times — resulting in a quality sacrifice in your finished product

Urethane molding overcomes each of these issues with a cost-effective and fast solution for prototyping and low-volume manufacturing. Let’s take a high-level look at how the solution works.

1) A mold pattern is created through 3D printing: Once your product has been designed (as it would be when using any other process), a mold pattern of your design is created using 3D printing. This is essentially a prototype of your product that will be used to create a silicone rubber mold.

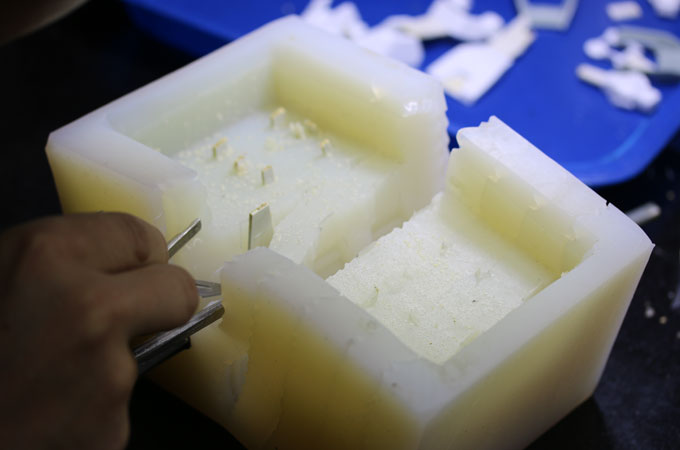

2) The silicone mold is created from the mold pattern: Instead of machining a mold from tool steel or aluminum, the silicone mold is actually created around the mold pattern.

3) The silicone mold is used for prototyping and low-volume production: In urethane molding, parts are cast from urethane in the silicone mold, rather than injection molded. However, functional prototypes and production-quality low-volume parts can be produced through the process.

Now that we have a better understanding of the urethane molding process, let’s examine the benefits:

Faster tooling production: Tool steel and even “soft metals” such as aluminum can be very time-consuming to machine. CNC machining involves extensive setup and machine time in order to accurately produce the correct mold shape. Silicone rubber molds can be produced in as little as a day or two, drastically reducing tooling production time from months or weeks. This lead time reduction of 95% or more can be truly game-changing for your production schedule.

Lower tooling cost: Setup and machine time are just the tip of the iceberg when it comes to the cost of your investment in a tool steel mold. (Note that tool steel molds are still the material of choice for long production runs of millions of parts.) The cost of the raw material itself also plays a major role in driving costs into the tens of thousands of dollars, or more. While this investment is a worthy one for production runs, it simply doesn’t make sense for prototypes and short production runs (which is why entrepreneurs often turn to “different but similar” processes). The liquid silicone rubber used to create these molds is much more cost effective, and the mold itself is more easily (and thus inexpensively) produced.

Ability to use 3D printing to cut lead times: In the past, silicone molds could be created with mold patterns made from metal, wood or other materials that took extensive time to create. The long lead times of creating the mold pattern often made urethane molding just as problematic as other processes. With 3D printing, mold patterns can be created in as little as 24 hours, and the versatility of 3D printing means that these patterns can serve as rudimentary prototypes in ways that other materials often can’t.

Easier iteration: Prototyping should be a multistep process involving several iterations (at least three, as a rule of thumb), in order for you to get the maximum benefit out of your investment in this critical part of product development. Creating one prototype and then attempting to fix any problems identified later on, in production, is a surefire recipe for disaster, to the tune of rejected parts, wasted time and material, and escalating tooling modification costs. The benefits of urethane molding mean that it’s much easier to go back and iterate on your initial design — new mold patterns can be easily created, and new silicone molds quickly and cost-effectively produced around them. Faster and easier prototype iteration means increased quality for you and your end customers, as well as a much faster time to market.

Manufacturability assessments: Although the casting process with urethane molding is slightly different than the injection molding process, the two bear many more similarities than other potential processes. You’re more likely to be able to use similar or identical materials between the two processes (thanks to the thermoset nature of LSR, it can handle the very hot temperatures required to liquefy the urethane material), meaning that you can identify any potential production issues much earlier.

Ability to manufacture production-quality parts: The nature of urethane molding and the materials that can be used in the process mean that it’s suitable not only for prototyping or short test runs, but also for low-volume production runs. The lead time differences that you save when using urethane molding instead of more traditional molding materials and processes — which may be unnecessary for your needs and thus an unworthy investment — can be vast. It’s well worth your time to consider the time and cost benefits of low-volume urethane molding as a production process, especially if you’re introducing a new product.

As in most manufacturing scenarios, the “right” process depends on your specific needs, business goals and product requirements. In the correct application, urethane molding can help get your product to market much faster, while providing a boost to your bottom line.