Prototypes serve a wide range of functions — it’s a big part of the reason why they’re so important to the development and success of your product. They can help you visualize, refine and develop your product; they can let you test different materials and formulations; they can give you a real-world look at its functionality; and they can help you decide on the end manufacturing process that you’ll use for production — to name a few.

One of the main benefits of prototyping, though, has less to do with the development of your product and more to do with the business side. When it comes to actually selling your product, a prototype can be an invaluable asset for a number of reasons. We’ll cover those reasons shortly.

One of the main benefits of prototyping, though, has less to do with the development of your product and more to do with the business side. When it comes to actually selling your product, a prototype can be an invaluable asset for a number of reasons. We’ll cover those reasons shortly.

First, let’s serve up a quick refresher on the many other advantages of prototyping. It’s a critical part of your product development cycle, but it often doesn’t receive the attention that it should. Here’s why you should avoid that pitfall:

- Prototyping identifies weaknesses in design and construction. By discovering potential issues in a prototype rather than a production-quantity run, you can save yourself the cost and pain of failed products and wasted time.

- Prototyping lets you perfect your design on the fly. An iterative process yields a much better end product, especially when compared with a process that doesn’t include testing and basically ends up hoping that the end product succeeds. Prototyping provides a low-cost and low-risk way to continually test and improve your design.

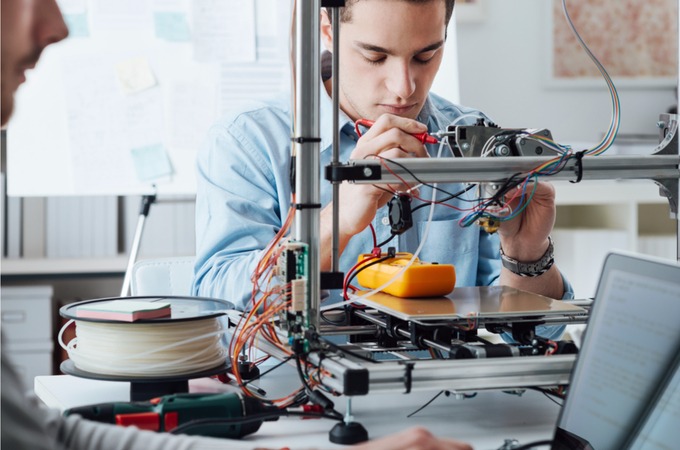

- Prototyping gives you an inside look at your production process. Whether it’s 3D printing, injection molding, CNC machining or another process, different types of prototyping can show you exactly how your production process will run in a way that data and numbers cannot.

- Prototyping keeps overall costs down. Trial and error in the prototype stage will always be less costly than moving to production with uncertainty. Don’t jump the gun and move to production earlier than you should. Be sure to invest the time and upfront money to ensure better results and ROI later.

On to the subject at hand: using your prototype to sell your product. How can a prototype help you begin the all-important process of sales and marketing, fulfilling the initial promise of your concept? Here are some of the ways:

A prototype does what a drawing can’t. Even the most advanced modeling software and the most intricate designs are, at their core, two-dimensional. Even an immersive, virtual reality representation of a product is still a digital recreation. The tangibility of a prototype simply can’t be replicated on a computer or in a drawing.

None of this is to say that drawings and CAD or other models aren’t an important part of your development process. Countless great ideas have started as napkin sketches, and a CAD modeling will help you get your idea ready for the prototype stage. Yet when the time comes to actually show your concept to potential investors or customers, there’s nothing like a prototype to illustrate what you’re saying.

None of this is to say that drawings and CAD or other models aren’t an important part of your development process. Countless great ideas have started as napkin sketches, and a CAD modeling will help you get your idea ready for the prototype stage. Yet when the time comes to actually show your concept to potential investors or customers, there’s nothing like a prototype to illustrate what you’re saying.

A prototype can legitimize you. Whether we’re talking about investor pitches, pre-sales meetings or crowdfunding campaigns, a working prototype can often be an elusive key to legitimacy. Showing that you’ve already put in the time and investment on your end to go beyond just a product concept can make a big difference to those who believe in you and your idea enough to support it. If your audience isn’t aware, you can explain it to them: A prototype is the culmination of months or years of R&D and product refinement. It represents an investment on your part. This gives your audience all the more reason to trust you enough to work with you financially (or buy your product).

A prototype can help you shore up important legal business considerations. A key part of product development is obtaining a patent for your concept. A patent ensures that the credit (and payment) for your concept goes to you, and gives you legal protection against infringement on your idea and design. Prototyping your product in preparation for filing a patent with the United States Patent and Trademark Office (or your local governing agency) can help ensure that the patent is accurate and successful.

For example, you wouldn’t want to file a patent and then discover a design flaw either later in development or during production. You’d have to fix the flaw, and also either update or replace your patent — both of which are tedious and time consuming. Having a working prototype that you’re confident in can help you file a more robust patent, a key component of the eventual sale of your product.

A prototype can be an important part of your funding campaign. Almost everyone knows of at least one product that got started on a crowdfunding page like Kickstarter. You may have even backed such a project yourself. Think back (or take a look at a crowdfunding site) — would you be more likely to fund a product where the creator already had a video of a working prototype? You probably would, and with good reason. Especially in the digital realm, seeing a person interacting with the actual product makes it seem that much more real, and that much more worthy of your investment. If you don’t already have a prototype, you can set that goal as a benchmark in bringing your product to production. You could even offer prototypes as rewards for backers (though not, to be sure, as a substitute for the finished product), if your product and your process make that feasible.

A prototype can be an important part of your funding campaign. Almost everyone knows of at least one product that got started on a crowdfunding page like Kickstarter. You may have even backed such a project yourself. Think back (or take a look at a crowdfunding site) — would you be more likely to fund a product where the creator already had a video of a working prototype? You probably would, and with good reason. Especially in the digital realm, seeing a person interacting with the actual product makes it seem that much more real, and that much more worthy of your investment. If you don’t already have a prototype, you can set that goal as a benchmark in bringing your product to production. You could even offer prototypes as rewards for backers (though not, to be sure, as a substitute for the finished product), if your product and your process make that feasible.

A prototype is such an important component of the production process that it can be easy to overlook the ways in which it can directly contribute to the sales and marketing of your product. As you work toward getting your product to market, be sure to consider all the ways in which this fairly early stage of the process can pave the road for success later.