For many manufacturing scenarios, injection molding is the best choice on many fronts: speed, cost and product reliability. The process is perfectly suited when large quantities of highly repeatable, consistent parts are needed at a relatively low per-piece cost. The versatility of injection molding does not, however, mean that it’s without potential pitfalls. Manufacturers and potential entrepreneurs with new product concepts can run into any number of problems without properly considering all aspects of the process, leading to inferior part quality, manufacturing delays and unplanned cost overruns.

Be sure to avoid the following mistakes when designing for injection molding, and enable yourself to take full advantage of the benefits the process offers.

1) Not designing for manufacture

While several points below will cover more specific and related areas of manufacturability, the importance of this step demands attention. Remember that a sketch or a concept is quite a different thing from a finished part. There are practicalities of design and manufacturing to consider when moving your idea to reality — don’t overlook them.

2) Not having multiple design iterations

Rarely — if ever — is a part ready to be manufactured after the first design concept is completed. Even if a part can be manufactured, that doesn’t mean that it should. An iterative design process can lead to breakthroughs in quality, efficiency and even function — especially when engineers and other experts are consulted in these early stages.

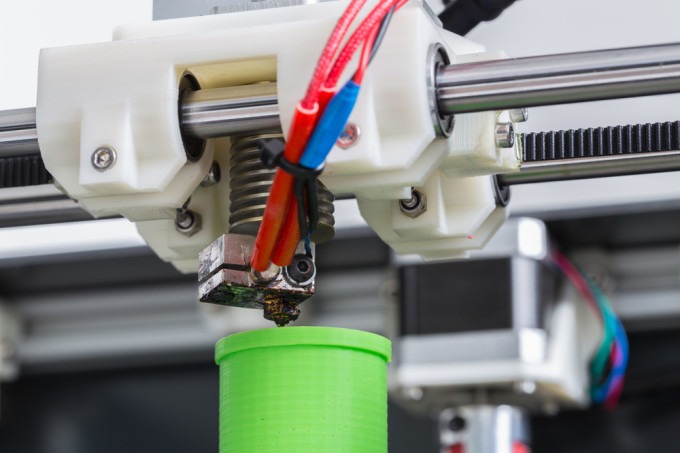

3) Not prototyping

One of the best ways to test for manufacturability and quality is by having a prototype of your part created. Even if, for instance, 3D printing and CNC Machining are used instead of injection molding (a much more cost-effective choice for prototyping), you are able to gauge the structural integrity of your part, the form of it, and other critical aspects that will come into play during production. Rapid prototyping allows for easy, efficient testing throughout multiple design iterations.

4) Not considering draft

Draft is one of the more practical considerations in designing parts for injection molding. Essentially, incorporating draft into your part design means that you are tapering or otherwise making the piece more conducive to easy release or extraction from the mold. Parts that are difficult to remove from a mold are more susceptible to damage and can increase cycle times, offsetting some of the benefits of injection molding.

5) Not properly planning wall thickness

The raw material in injection molding is a plastic that has been heated to a liquid state. With differences in wall thickness, the liquid will cool back to a solid at different rates — and if the differences in thickness are abrupt enough, it can lead to inaccurate part production as the still-melted material from thicker wall areas runs to the already-cooled thinner walls. Which also leads to sink marks and warping. If you are unable to design uniformly thick walls, be sure to only change thicknesses gradually throughout your part.

6) Not considering all types of molds

Injection molds are typically manufactured from tool steel or other strong metals, and these molds are built to last. One high-quality mold can produce millions of parts with little to no degradation in quality. However, if you’re looking to manufacture in smaller quantities — whether for prototypes or testing, or simply because you don’t expect demand in the millions – you may want to consider a prototype mold. Prototype molds typically use a lower grade metal and are manually ejected. That is why prototype molds have a lower upfront cost that allow you to make smaller quantities.

7) Not taking overall costs into account

It’s always important, however, to not be blinded by low upfront costs for any aspect of your project. Overall cost is the most important factor to look at — whether it’s the lifespan of your tooling, the materials you choose, or the suppliers and distributors you work with. It’s not always the case, but low upfront costs can hide more expensive problems later. Be sure to take the long view with your product.

8) Not choosing materials properly

The versatility of injection molding means that you have an incredibly wide range of plastic materials to work with. Take advantage of this opportunity to research and choose the exact best material for your part. Consider the requirements and environment your part is intended for. Strength, flexibility, temperature range, and clarity are a few common requirements that affect plastic choice, manufacturing process, and even the part itself. Making the right, informed choices can improve lead times, part quality and cost efficiency. If you need help choosing a plastic, you can find assistance here.

9) Not considering the mold’s gate

9) Not considering the mold’s gate

One of the practical considerations of injection molding: there has to be somewhere to inject the liquid plastic. This feature is called the mold’s gate, and should not be overlooked or left until the end of the design process. Gate location and removal process are important considerations to make not only in designing your mold, but even, in some cases, in designing the part itself. Consider whether remnants of gate removal will be acceptable on the parts you produce; or whether further finishing will be required, and whether automatic or manual removal is the right process.

10) Not researching your supply chain

Another area that factors into the overall cost of manufacturing your product. Look at all aspects of vendors before deciding to work with them, not just pricing:

Do they have a good-quality reputation?

- • Do they have a good-quality reputation?

- • Do they have any specialties?

- • Have they worked with companies like yours before?

- • Will they take your needs and expectations into account?

- • Is their location conducive to the production and shipping cycles you will need to adhere to?

11) Not designing the mold properly

We’ve talked about gate and draft, but other factors of designing your mold are important to consider, as well. All too often, inferior molds are created in the interest of lowering upfront costs. These inferiorities can range from too-thin back walls, to subpar material choices. It is vastly more expensive to repair or replace a mold (and make up for lost production time) than it is to do it right the first time. This is why it is so important to partner with the right vendor who will design the mold properly for you. It is much more efficient to review a mold design created with structure and quality in mind.

12) Not considering all types of plastic injection molding

The flexibility offered by injection molding is not just limited to materials. The process covers a broad array of capabilities that might be more specifically suitable for your product. Overmolding, for instance, can be a better way to create complex parts than a one-step process. Insert molding, is highly efficient and a great alternative to the assembly of complex parts that would be added through soldering or adhesives. Rotating platen injection molding can be useful for the creation of soft touch applications. High speed injection molding is ideal for the creation of a high volume of plastic parts quickly and efficiently.

Be sure to also carefully consider who you choose to fulfill your injection molding needs — expertise can help you navigate the options available, and avoid these mistakes.

9) Not considering the mold’s gate

9) Not considering the mold’s gate