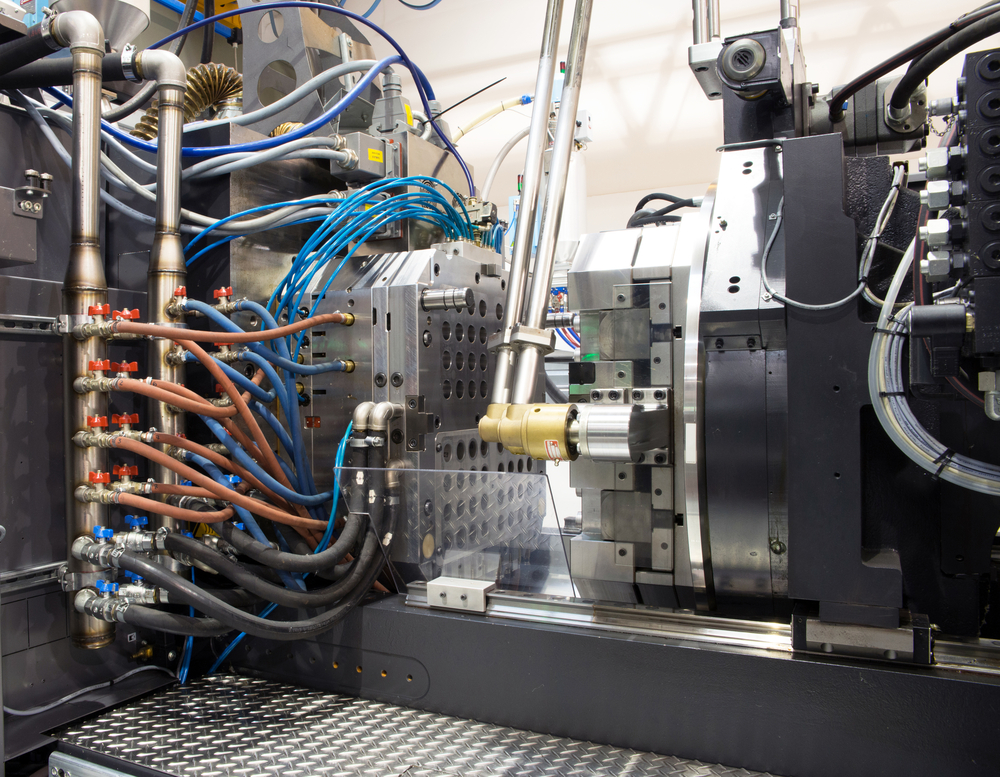

Injection molding process monitoring and process control can help you achieve several goals: improved process quality, higher-quality products and lower overall costs — to name a few. Injection molding process control can also help you stay on top of secondary aspects of your manufacturing process, such as injection mold life cycle and other equipment factors that play a role in different areas of your budget and overhead.

If you’re not familiar with injection molding process monitoring, or have heard the term but aren’t quite sure about the full meaning, let’s back up and take a look at exactly what it is. On the surface, the term seems self-explanatory: it’s a way of monitoring quantitative aspects of your molding process. However, there’s more that makes up the meat of what injection molding process monitoring and control do — and what the benefits are.

The components that comprise an effective injection molding process monitoring system can include:

- • A system to record all quantitative aspects of your molding process (there are many — more on this below)

- • A data storage method capable of keeping (and ideally, organizing) a large amount of data accessible

- • Personnel with the tools and knowledge to convert this large amount of data into actionable practices

Note that without this last aspect, injection molding process monitoring is unlikely to have much of a payoff. Massive amounts of data will be collected through a process monitoring system — representing a huge opportunity to provide insights into your processes that wouldn’t otherwise be available. However, without the data engineering expertise to make sense of this information, understand how it all fits together, and most importantly, use it to improve your processes and products, the data that’s been collected doesn’t have much value.

As mentioned above, injection molding process monitoring can record data about many aspects of the process. These include:

- • Injection pressure

- • Melt temperature

- • Mold temperature

- • Air temperature

- • Screw position

- • Filling time

- • Packing/holding time

- • Cooling time

Beyond this list, there are even more factors that can be recorded by a monitoring process. The ones that you choose to look at will differ based on the particular data application you require. For instance, you may need to:

- • Troubleshoot recurring part quality or rejection issues

- • Identify and remedy process inefficiencies

- • Monitor mold performance and life cycle

- • Conduct more proactive quality control

In a bit, we’ll touch on each of these applications, benefits and more. Before getting deeper into the specific applications, though, we’ll cover two concepts that drive the ways your data can be analyzed and put to use:

- • Multivariate analysis: Multivariate analysis models several process variables simultaneously, to provide an overall picture of the performance of a process. Multivariate analysis will compare real-time results to optimal data points, illustrating what benchmarks the process is hitting as related to where it can and should be. A key benefit of multivariate analysis is that it factors in several variables at once, and can provide insights as to how they are working together and affecting one another. Contrast this with analysis of a single variable, which can provide data about a process but does so in a kind of vacuum, not taking other factors into account.

- • Real-time process monitoring: Real-time process monitoring continually and simultaneously analyzes data as it is being collected, and allows you to make adjustments on the fly, on a cycle-by-cycle basis, rather than at the conclusion of a full production run. This allows you to see improvements and optimizations more quickly.

These practices work together to produce a number of useful benefits for your injection molding processes, which can result in lowered production costs and improved part quality. These benefits include:

- • Troubleshooting persistent or recurring issues: Analyzing the large amounts of data provided in process monitoring can shed light on the causes behind common injection molding defects, and can, in many cases, diagnose and troubleshoot them much more quickly and accurately than other methods. For instance, if burn marks are a common issue with a particular part, a multivariate analysis can help determine whether lowering the mold temperature, lowering the material temperature, or improving venting in the mold will provide the fastest and most effective remedy.

- • Identify and remedy process inefficiencies: Small inefficiencies in your molding process can add up to big amounts of wasted costs in the long run. Even a minor miscalibration in cycle time, for instance, can lead to hours of lost machine time over thousands or millions of cycles. By comparing the overall picture of your actual process with the optimal process, these small inefficiencies can be readily identified. The benefits of real-time monitoring and adjustment mean that they can also be remedied almost immediately, helping you get the most value out of your process. In fact, many injection molding process monitoring and control systems can identify trends in inefficiencies in a process and can automatically correct them in-process — with little or no need to shut down production for adjustments.

- • Monitoring mold performance and life cycle: Based on the material, size, shot count and other factors, a mold will be rated for a certain life cycle duration. This assessment, however, doesn’t take into account the practical factors of everyday use that will affect the life cycle of a mold. With injection molding process monitoring in place, you can get a more realistic picture of your mold’s performance and maintenance status. Identifying factors that may reduce the mold’s life span can help you shorten maintenance cycles and get the most value out of your investment. Similarly, using the data collected to learn whether a mold may still be useful beyond its rated life cycle — for instance, if all data indicates that it is still performing at an acceptable tolerance — can prevent situations where molds are replaced or repaired unnecessarily.

- • Proactive quality assurance: Instead of inspecting parts to determine acceptance/rejection after they are produced, process monitoring and control can be set to detect unacceptable variables and automatically reject a piece. Earlier detection can also lead to fewer rejections.

While process monitoring can streamline and automate many aspects of production and quality control, remember: A monitoring system and the data it produces are only as good as the people on hand to analyze and enact the results.