3D printing has seen some pretty big advancements over the last few years. You can now buy your own compact 3D printers that will sit on your desk, you can 3D print ice cream and chocolate into delicious shapes, and doctors are using this technology to save and improve lives.

While medical researchers are focusing on bioprinting, making blood vessels and organs, some engineers are thinking much, much bigger:

A design and engineering company in Shanghai is working 3D printing houses. And not tiny houses either: each of the 10 houses they can print in a day is 2,100 square feet (twice the size of my apartment) and only costs around $5,500 to build.

Another researcher working on ways to quickly, cheaply, and safely print houses is University of Southern California professor Dr. Bherokh Khoshnevis. One of his major projects is what he calls contour crafting—3D printing houses but with more details (like curved walls).

Khoshnevis sees his process having several applications: emergency housing that can be built quickly (his 2,000 square foot house can be finished in less than twenty-four hours), low-income housing in developing countries, and of course commercial applications.

But his final idea is what won him a grant from NASA.

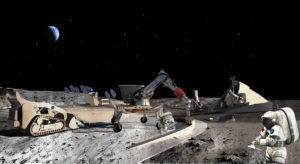

3D printing buildings in space.

NASA has been talking about building on the moon since at least 1994, when they released a study on building materials [1] that can be easily created with materials easy to find on the lunar surface. Their idea at the time, which seems to still hold up 20 years later, is to use sulfur concrete. This is simply a mixture of sulfur and whatever rocks or dust that can be easily found. With the ingredients mixed together and heated to a low 284 Fahrenheit (140 C), the concrete can be put in place. This type of concrete cools very quickly, which means the building will be completed faster. Sulfur concrete is also very strong and resistant to some acids that can erode traditional concretes.

Utilizing resources that are already available on the planet means that NASA saves money on rocket fuel by not having to send what they need through space and is called in-situ-resource utilization.

And since the gravity is lighter on Mars and the moon, that the buildings put up with less stress and can last longer.

Khoshnevis is working on a way to build important infrastructure on Mars, what settlers would need once they arrived: landing pads, roads, blast and shade walls along with thermonuclear/micrometeorite shields to help protect any human inhabitants. [2]

Infrastructure is the first step towards fulfilling one of NASA’s 1994 dreams: building an observatory on the moon and to use it as “a stepping stone to other planets where spaceships will refuel and be launched from the surface of the moon.” [1]

So someday people are going to be annoyed that they have a layover on the moon.

NASA clearly hasn’t let go of their dream to get people living in space. In 2012, they launched the Mars rover Curiosity, equipped with a “radiation detector to measure the environment astronauts will encounter on a round-trip between Earth and the Martian surface.”

NASA is also sending lander mission InSight to get a look at the “deep interior” of Mars in 2016.

In 2020, another rover will be heading to Mars equipped with tools to “conduct unprecedented investigations in science and technology as well as capabilities needed for humans to pioneer the red planet” (emphasis mine). [3]

NASA also says in this same article:

The Mars 2020 rover will help further advance our knowledge of how future human explorers could use natural resources available on the surface of the Red Planet. An ability to live off the Martian land would transform future exploration of the planet. Designers of future human expeditions can use this mission to understand the hazards posed by Martian dust and demonstrate technology to process carbon dioxide from the atmosphere to produce oxygen. These experiments will help engineers learn how to use Martian resources to produce oxygen for human respiration and potentially as an oxidizer for rocket fuel.

I’m pretty sure I’ve seen this exact same idea on the SyFy channel.

Another important step is testing how 3D printing will work in different levels of gravity—starting with zero. Next month, NASA is sending 3D printing capabilities to the International Space Station to stay until October 2015. This will help test how the materials work in zero gravity. Having a better understanding of how 3D printing works in space will not only help with contour crafting on Mars but will also help future deep space explorers be able to repair their ships as they fly—having in-spaceship manufacturing capabilities will keep them safe and help extend the lives of their missions. [4]

While having a fully functional colony on Mars (or the moon) probably won’t happen for a while, it could happen in our lifetimes. And the building of infrastructure could begin in just ten years.

So let me ask—would you move to Mars if you could? (tweet to ask your friends)

References:

[1] Husam A. Omar and Mohsen Issa (1994). “Production of Lunar Concrete Using Molten Sulfur” (PDF). In Rodney G. Galloway and Stanley Lokaj. Engineering, construction, and operations in space IV: Space ’94; Proceedings of the 4th International Conference, Albuquerque, New Mexico, February 26–March 3, 1994 2. New York: American Society of Civil Engineers. pp. 952–959.

[2] Behrokh Khoshnevis. “ISRU-Based Robotic Construction Technologies for Lunar and Martian Infrastructures.” NASA.

[3] “NASA Mars Curiosity Rover: Two Years and Counting on Red Planet.” NASA. 5 August 2014.

[4] “3D Printing In Zero-G Technology Demonstration (3D Printing In Zero-G).” NASA. 5 August 2014.