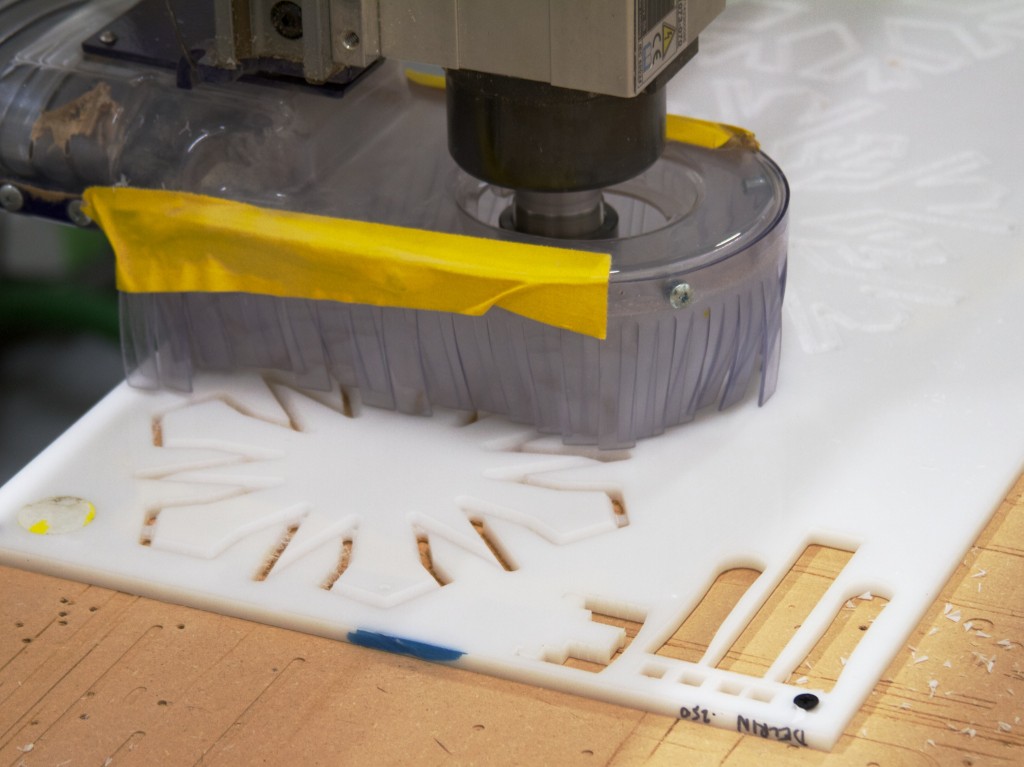

Plastic CNC machining is an example of a subtractive manufacturing process. When you place your order with RevPart, we begin with a solid piece of plastic, load it into the machine, and begin cutting. The machine removes plastic layer by layer, following the guidelines in your CAD file, and eventually reveals a perfectly formed product.

This is different from an additive manufacturing process, like 3D printing, where we start with liquid material and build your part layer by layer. Sometimes this can be cheaper, like if you just want one or two items…but if you want a fully functional prototype, you’ll probably want it machined.

This type of machining has been around since the 1940s. Back then, machinists had to manually translate the designs onto a strip of paper with punches on it (similar to how a player piano works) and feed the paper into the machine to create parts. Thankfully, technology has advanced so that now everything is done with a computer!

Because of this increasing automation, the machined parts have a high level of consistency with very few errors being made in the process. The CAD (computer aided design) file you provide us has all of the information our CNC machines need to operate. It tells the machine exactly where to cut and how deep the blade should move, following a set of numbers embedded into the design.

These numbers (or coordinates) are actually how CNC machining got its name…computer numerically controlled machines!

Getting your part made with a CNC machine at RevPart might just be your best bet for getting an inexpensive but fully functional prototype. It tends to be cheaper than injection molding and works at a higher functional level than 3D printing.

If you think plastic CNC machining is right for your product, ask for a quote! We’ll return your request in 24 hours so that you can have your prototype in your hand faster.