A few months ago, we took a look at some of the easiest ways to help you get more done with SOLIDWORKS, sharing some of the best keyboard shortcuts and functions that we’ve come across. This time around, we wanted to explore even more ways to get the most out of your CAD modeling software, going beyond shortcuts and looking at the tips, tricks and even just some core features that we feel are the best “productivity hacks” around — those that add value by helping you get your work done faster.

For plastic injection molding and other functions, SOLIDWORKS is a huge aid in communication both among internal departments — like design and engineering — and between clients and their manufacturing partners. Read on for how it can help you:

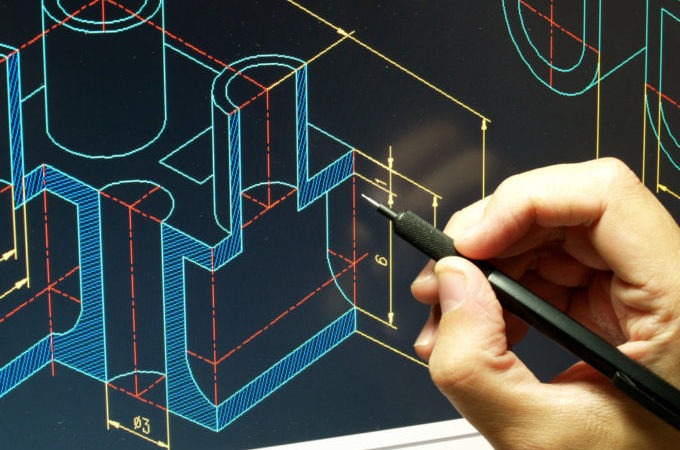

Two-dimensional and three-dimensional conversion. The latest versions of SOLIDWORKS have achieved some pretty sophisticated — and extremely helpful – methods of converting between 2D and 3D drawings, using intelligent technology to help users convert from 2D drawing to 3D models without the need for completely manual 3D drawing creation. They’ve also reached a breakthrough in working around one of the biggest areas where errors occur: converting from 3D models to 2D drawings. A feature called SOLIDWORKS Model-Based Design (MBD) lets you move to the production/manufacturing phase using 3D models as a reference — not 2D drawings. Working directly from 3D models will help move your manufacturing process from concept and design to the actual production process more seamlessly.

New and updated mates. If you haven’t taken a look at Mates in SOLIDWORKS lately, now is a great time to do so. Even if you’ve checked them out in the past and haven’t found much use for them, SOLIDWORKS has been consistently improving and upgrading the Mates available to provide utility for a wide range of applications.

What if you’ve never used SOLIDWORKS Mates before? Here’s a quick introduction — which just may make your life a lot easier: Mates essentially let you link two or more selections in a specific way, so that changing one applies similar, realistic changes to the other according to the properties of the Mate (or, in some cases, prevents you from changing one or the other). Mates make it much easier to modify and try different part and product configurations without worrying as much about accounting for every effect of a small change — Mates take care of it for you.

Three-dimensional printing. The introduction of 3D printing support was a huge step forward for SOLIDWORKS — one that keeps it squarely in the middle of the way manufacturing and design continue to grow and evolve. For all of its ease and convenience, 3D printing is certainly more involved than the “upload drawing, get product instantly” reputation that it still has in some circles. The realities of physics and manufacturing for design mean that viable, high-quality 3D printed parts and products need to be well-designed, planned and thought out before they are created, and SOLIDWORKS’ support for 3D printing provides an easy way to get those things right, in a familiar interface. The next two points take a closer look at how SOLIDWORKS can help with your 3D printing design.

Three-dimensional print bed. Whether a part contains complex geometries or is a relatively simple design, the print bed is often one of the most important parts of a successful product creation. Essentially, the print bed is a non-solid “web” or “matrix” of 3D printing substrate that is designed to be removed, and exists to support those areas of a product or part design that cannot freely stand or support themselves during the additive 3D printing process. Examples might be protruding part designs, curvatures, or any other component that would otherwise weaken or collapse if not properly supported.

The most recent version of SOLIDWORKS helps determine where and how the print bed is required, and can even help save on material costs by determining just how much substrate is required to support the part component in question.

Three-dimensional print resolution. The print resolution of a 3D printed part is an indication of the density of the material being applied to create the required output. Just like any 2D paper printer, lower resolution means a lower density (and potentially a lower quality, although that’s not necessarily a bad thing, depending on the purpose and function of the product being 3D printed – for aesthetic prototypes, for instance, just as for first drafts of 2D artwork, lower resolution is often fine).

Higher resolution 3D printing provides more density and thickness within a part, which can prevent weakening or collapse. SOLIDWORKS can help you adjust and determine the proper print resolution for 3D printing based on the dimensions and design of your product, as well as the required strength and quality of the end result.

Collaboration functions. Compatibility, email attachment sizes and other logistical concerns — these are all collaboration requirements that can confuse employees while working on a new product. SOLIDWORKS makes it easy to share completed and in-progress projects across an organization, or with investors and other manufacturing partners. The eDrawings feature helps combat large file sizes with compressed yet still high-quality, shareable snapshots of work in progress. You can also export SOLIDWORKS drawings to a number of other formats — even those for other CAD programs. Getting everyone on the same page and eliminating hardware and software issues is often one of the biggest roadblocks to collaboration — be sure to fully explore the options that SOLIDWORKS offers to help you overcome them.

Real-world simulation. Your new product is only as good as the way it responds to the stresses of the environment it’s designed to work in, whether that’s extreme heat, precipitation, high pressure — or just a new children’s toy. SOLIDWORKS offers premium features that can help you run the environmental testing you need to be sure that your product, part or component will perform as your customers need it to — thus giving you a better chance of success. While environmental testing can often be difficult, requiring outside expertise and services to be thorough and accurate, this SOLIDWORKS feature lets you do much more on your own.

There’s really no end in sight to the features and additions that keep SOLIDWORKS at the forefront of the technical drawing and design industry. Hopefully you’ve found a few tips here that will let you get even more out of this already-indispensable platform.