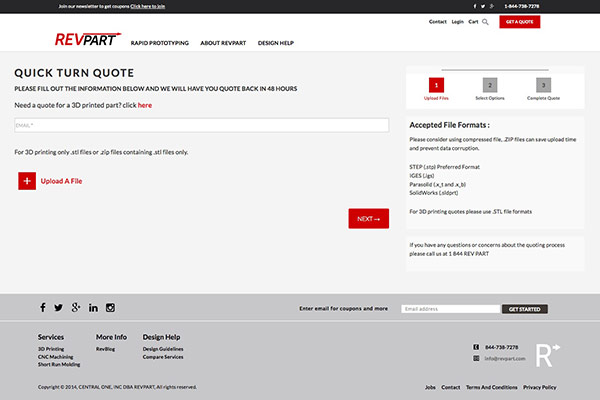

Beat your deadlines with our quick-turn custom plastic injection molding services

- Get a quote in less than 48-hours

- Get molds in 10 – 18 days

- Parts delivered in a couple days

- 5K and 10K shot prototype molds

What makes us Different?

When you’re looking for short-run or injection molded parts, time is usually of the essence — but so, as always, is quality. Prototype injection molding lets you enjoy both benefits, meeting your fast turnaround needs through a process that provides some of the most reliable, high-quality products available.

Fast turnaround

- Prototype molds in as few as 10 days

- Parts produced in just two days

- We specialize in short, fast-turn runs — no order too small

High repeatability

- Plastic injection molds can last for hundreds of thousands of parts, with identical results every time

- Ready to move forward with your prototype? We offer production quantity runs as well, with the same dedication to quality.

- Even tight tolerances remain consistent from piece to piece

Versatility in materials

- Plastic injection molding is suited to a vast array of materials, formulations and colors

- Achieve varying durometers, consistencies and finishes, thanks to broad material selection

Our Capabilities

RevPart is more than just another CNC plastic machine shop. RevPart offers conventional plastic injection molding service from 75 to 500 tons, as well as high-speed, all-electric injection molding with wall thicknesses down to 0.3 mm. We specialize in providing high-quality, quick turn prototype injection molding and short-run parts in a fraction of the time of other facilities, and will never turn down a job for being too small. Types of injection molding services that RevPart provides include:

- Overmolding

- Two shot molding with rotating platen

- Double shot molding

- Insert molding

- Conventional molding from 75 tons to 500 tons

- High speed injection molding

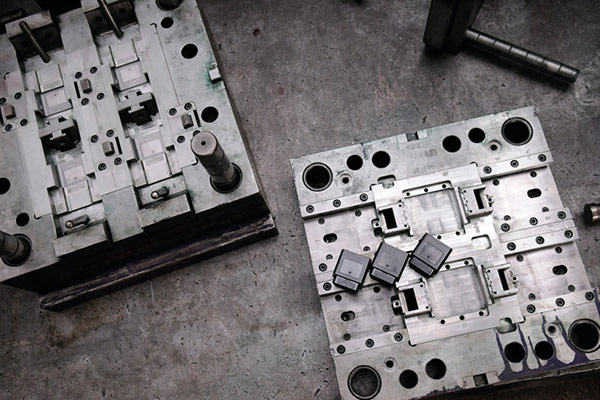

How Does Injection Molding Work?

RevPart’s Injection Molding Process

1. Get a quote

2. Build the Injection Mold

Even for prototype parts or low-volume plastic injection molding, quality is critical. RevPart chooses the appropriate material to remain cost-effective while also preventing cracking, disfigurement or other damage to your investment. In fact, our prototype molds come with a 10K shot guarantee.

3. Make the injection molded parts

Our CNC machines are ready and waiting to manufacture your parts, with capacities for any run, small or large. The speed offered by our plastic molding process goes to waste when your order goes into a long queue — but we make sure you can get parts in as little as two days once your injection mold is completed.

Material options

Plastic injection molding is a versatile process, with the ability to handle an extremely wide range of materials. RevPart is ready with the expertise to match materials and formulations to your product needs.

Colors:

Pantone matching for any color. Multiple color parts available via two-shot molding, overmolding, and insert molding.

Finishes:

Capabilities to texture the mold according to any SPI finish or MT finish. The repeatability of plastic injection molding ensures consistency, even for detailed finishes.

Resins:

Achieve various specific qualities for your part through resin selection, including durometer, flexibility and more. Potential for food grade, medical grade and other specialty parts.

Value added options:

Fulfill other requirements beyond plastic injection molding, including spray painting of parts, pad printing, screen printing and more.

FAQs

Q: Should I choose plastic molding for my product?

A: Plastic molding is an excellent choice for your product if it requires high precision with tight tolerances and if a high degree of repeatability is an important concern. Plastic molding also offers fast, efficient production speeds once the tooling for the product has been created (which may require some lead time), a low cost per part and a wide range of material choices.

Q: What kind of certification should I look for in a plastic molder?

A: Certifications mean that a manufacturer has made the effort and investment to ensure that their processes and services meet the highest standards in the industry. In a commodity field such as plastic molding, certifications can be one of the best gauges of the service and quality that you can expect to receive from your chosen supplier. Some key certifications to look for include ISO and TS certifications, including certifications specific to the industry in which you operate.

Q: Why use injection molding?

A: Injection molding offers a number of advantages in the right scenarios. The process offers one of the lowest costs per part, even for lower volumes. In fact, with the right mold material, low-volume plastic injection molding is just as cost-effective as competing processes. Injection molding also offers a broad, diverse range of material choices with different material properties to suit your application, and it is one of the fastest and most efficient processes available.

Q: How do I choose the right resin for my parts?

A: The right resin for your part will be dictated by the product’s application and requirements. While you will often have an idea of the right resin, especially once you become familiar with the options available, it is always a good idea to consult with an expert in the field to ensure the right choice for your part. Resins are generally broken down into amorphous and semicrystalline types, with numerous options available in each category. Factors to consider include environmental resistance needs (heat and cold), strength, flexibility, hardness, material resistance, special requirements (for example, food grade) and anything else unique to your product.

Q: What secondary services are offered on my injection molded product?

A: RevPart offers a wide selection of secondary services for your injection molded product, including CNC machining, CNC milling, CNC turning, short-run molding and more. Our expertise in these areas help make us a true one-stop shop for your molding needs.