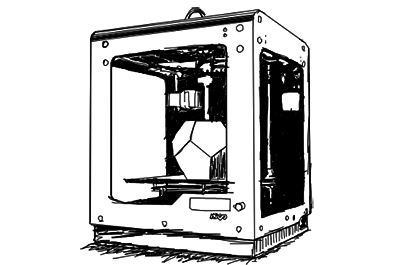

3D Printing Process

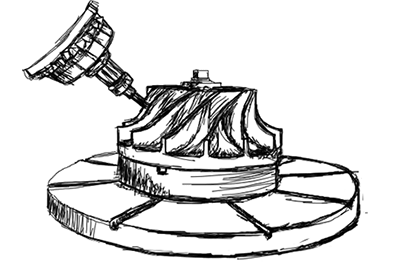

CNC Machining Process

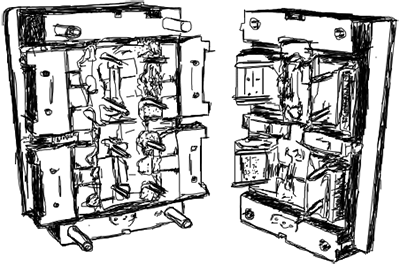

Prototype Molding Process

Step 1 - 3D Drawings

Get your napkin sketch or idea professionally modeled in 3D software. Popular 3D software includes AUTOCAD Inventor, SolidWorks and Creo.

Do you need help with drafting your idea into a 3D model? Contact us and we can help you.

Step 1 - 3D Drawings

Get your napkin sketch or idea professionally modeled in 3D software. Popular 3D software includes AUTOCAD Inventor, SolidWorks and Creo.

Do you need help with drafting your idea into a 3D model? Contact us and we can help you.

Step 1 - 3D Drawings

Get your napkin sketch or idea professionally modeled in 3D software. Popular 3D software includes AUTOCAD Inventor, SolidWorks and Creo.

Do you need help with drafting your idea into a 3D model? Contact us and we can help you.

Step 2 - Request Quote

Use our simple 3 step process to fill out your contact email and upload your 3D files. During the quoting process you will have an opportunity to specify what types of prototypes, materials, and finishes you would like. After we receive the quote we will begin working on the prices based on your specifications. We will return the quote to you in under 24 hours.

Step 2 - Request Quote

Use our simple 3 step process to fill out your contact email and upload your 3D files. During the quoting process you will have an opportunity to specify what types of prototypes, materials, and finishes you would like. After we receive the quote we will begin working on the prices based on your specifications. We will return the quote to you in under 24 hours.

Step 2 - Request Quote

Use our simple 3 step process to fill out your contact email and upload your 3D files. During the quoting process you will have an opportunity to specify what types of prototypes, materials, and finishes you would like. After we receive the quote we will begin working on the prices based on your specifications. We will return the quote to you in under 24 hours.

Step 3 - Place The Order

We will send our quote electronically to your cart for your convenience. All you have to do is make some final selections like quantity, delivery time, and which parts you want before you place the order. We accept all major credit cards for the transaction.

Step 3 - Place The Order

We will send our quote electronically to your cart for your convenience. All you have to do is make some final selections like quantity, delivery time, and which parts you want before you place the order. We accept all major credit cards for the transaction.

Step 3 - Place The Order

We will send our quote electronically to your cart for your convenience. All you have to do is make some final selections like quantity, delivery time, and which parts you want before you place the order. We accept all major credit cards for the transaction.

Step 4 - Part Is Made

We will send our quote electronically to your cart for your convenience. All you have to do is make some final selections like quantity, delivery time, and which parts you want before you place the order. We accept all major credit cards for the transaction.

Step 4 - Part Is Made

We will send our quote electronically to your cart for your convenience. All you have to do is make some final selections like quantity, delivery time, and which parts you want before you place the order. We accept all major credit cards for the transaction.

Step 4 - Mold Building

The mold is designed, machined, and EDM in our in house tooling area. After the mold is complete it is loaded onto a injection molding machine where we shoot some first articles for testing.

Step 5 - Receive and Enjoy

Receive your part, inspect it and begin using it.

Step 5 - Receive and Enjoy

Receive your part, inspect it and begin using it.

Step 5 - Verify

A first article part will be sent to you for you to inspect. We also ship a First Article Inspection report FAI to detail out all the critical dimensions. The first article does not have a finish as it is just for dimensional inspection. Once the first article is approved we can move to the next step.

Step 6 - Texture

The mold is send to our texturing department to receive any textures or gloss requirements you may have. Once the mold is textured and verified we are ready for the next step.

Step 7 - Production

Parts are produced in production quantities and shipped in bulk packaging to you.

Step 8 - Receive and Enjoy

Receive your part, inspect it and begin using it.