Whether you’re a budding entrepreneur or an established business, launching a new product is both exciting and challenging. While your status in the marketplace, your standing as a business, and even your reasons for launching a new product may be different, the principles underpinning how to make a product successful are often the same.

Today, we’ll define what makes a successful product launch, regardless of whether you’re just starting in your industry or are actively expanding your product line.

1. Research your target market. When you’re wondering how to make your product successful, information is often your most powerful ally. The more information you have, the better equipped you are to manage your (and your investors’, managers’ and/or directors’) expectations and create a product that will meet a market need. It’s frankly unnecessary — especially in a day and age with a nearly unimaginable amount of data readily available — to enter into a new business venture “flying blind.”

Right from the outset, you should gather as much information as possible about the need for your new product concept. Market research firms can be a big help here, but you can also lay the groundwork (for free) simply by researching the existing marketplace. Some questions to ask yourself as you research:

- • Does my product, or a similar one, already exist?

- • What will differentiate my product in the marketplace?

- • Who would use my product?

- • What would they use it for?

- • Why should they use mine instead of another one?

- • What do consumers think about existing similar products? (via online retail outlets or other review sites)

- • How can I improve on what’s already out there?

- • How much are consumers willing to pay for existing products like mine? (And how much would they pay for a better one — yours?)

2. Set performance metrics. Information in the form of hard numbers and benchmarks remain your best friend here. The status of your product at any stage — from preproduction all the way to in-market — should never be a mystery, and the best way to keep everything transparent is to keep a series of progress goals/requirements in place.

Naturally, setting these benchmarks is the best way to keep your development and production process on schedule. It also breaks the product launch cycle into manageable chunks, and, ideally, builds in a series of review opportunities to assess and fine-tune your product and your progress. Once your product reaches the market, your performance metrics (which should be based on market research) can reliably show you whether your sales are underperforming or overperforming, helping you decide your next steps from there.

3. Get to know the manufacturing industry (and your manufacturer). If you don’t have a background in the manufacturing industry, the process of bringing your new product from concept to creation can seem pretty opaque. Fortunately, there’s a wealth of information out there to help the layperson with entrepreneurial aspirations navigate the path to making your product a reality.

It can also be a big help to take the time to really get to know your manufacturing partner. That means viewing your partner as more than a commodity in bringing your product to market — and, on the flip side, choosing a partner that views you as a valued client, not an invoice or a chunk of time on the production line. A good manufacturer adds value to its services by sharing its expertise in what it does, with the goal of optimizing your product and its launch. Whether that’s assisting in material choice, sourcing, process decisions and other aspects of the manufacturing process that you may be unfamiliar with, a helpful manufacturing partner can be a key asset in a successful product launch.

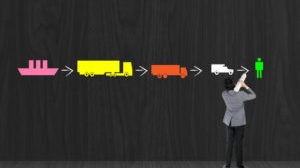

4. Take a good look at your supply chain. Supply chain is an aspect of the manufacturing process that can often seem “hidden,” though this shouldn’t be the case. Why? Because it’s one of the most critical aspects in a successful product launch and successful production down the line. Supply chain hiccups can cause delays in material deliveries, delaying your launch or the restocking of your product. Failure to properly research your supply chain can even cause regulatory headaches, if a supplier is sourcing material from embargoed or otherwise sanctioned areas, especially if you’re seeking government contracts.

Knowing that supply chain is important is a great first step in avoiding those issues. If a supplier or manufacturing partner isn’t willing to be forthcoming about its downstream suppliers, it’s probably best to move on.

5. Prototype. Never be tempted to forego important steps like prototyping in the service of hitting a launch date or a budget requirement. Prototyping — ideally, several iterations — should be built both into your timeline and your bottom line.

One smart way to maximize the return on your prototyping budget is to use rapid prototyping or 3D printing services. These processes use what’s known as “additive manufacturing” to reduce production time and material costs – there’s little to no setup involved other than uploading a CAD drawing, and you only need to pay for the material you use.

6. Test, test, test. This step applies to several aspects of the production process. For instance, consumer testing: conducting real-world interviews and sessions to see how the public will interact with and respond to your product. Consumer testing is a great way to escape any “bubble” that may have formed around you and your development team during the steps leading to your product launch.

Once you reach the manufacturing stage, quality testing is important, both for your process and the product itself. If you’re using a manufacturing process like injection molding, for instance, you (or your manufacturer) should test the molds to ensure that they will yield finished pieces that look and function the way you need. What’s more, post-production QA inspection is a critical step to ensure the safety and functionality of the finished pieces.

7. Have a plan to scale (or at least plan to have a plan). Here’s one of the most exciting post-production steps: Growth. This is likely one of the core reasons why you’re launching a product in the first place. It’s not unheard of to plan your growth strategy around your initial sales results, as long as you know that you’ll eventually need to make a plan, you should be fine. Some things to take into account as you plan to grow: personnel needs, equipment, infrastructure and facility requirements, balance sheet impact, distribution and warehousing/inventory planning.

As we mentioned at the start, information is one of your most powerful assets throughout a product launch, and with this information in hand, you’re even further along the road to success!