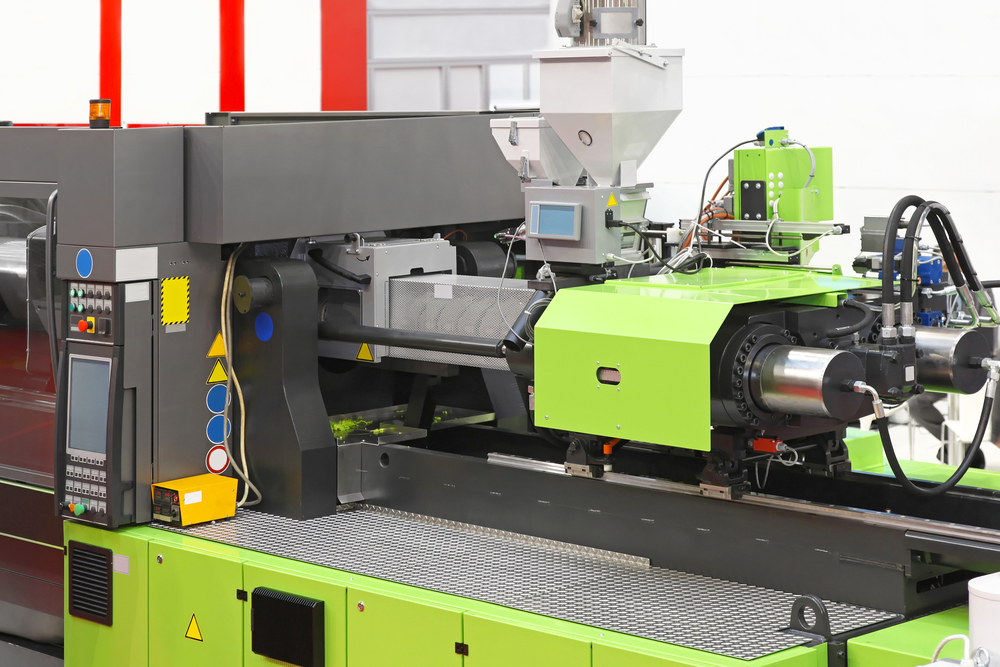

Injection molding defects: they happen, even to the most experienced and knowledgeable operators out there. Don’t listen to anyone who tells you that molding defects are purely symptomatic of inexperience or inattention — it’s simply not the case. Any number of causes can contribute to molding defects: standard process margins of error, differences from one batch of material to another, changes in machine calibration after repairs or maintenance, ambient environmental factors, and more. And yes, experience can play a role as well, but in a broad range of forms. For instance, a long-time operator working with a machine for the first time may not be familiar with its quirks and particularities, leading to unavoidable errors.

There are many types of injection molding defects, but some are more common than others. What this means in practice is that there are more factors that can cause some defects than others, and thus more ways to remedy them.

Below, we’ll look at five of the most common types of injection molding defects, and how you can prevent or repair them.

1. Flow Lines and Flow Marks

Caused by: Non-uniform cooling times and flow rates; excessively narrow part features.

Symptoms: Flow lines will typically appear as discolored “bands,” or sometimes “wavy” discolorations, on the surface of a part, usually near the mold gate. Flow marks are a more isolated version of flow lines where discolorations appear, but not around the entire circumference of a part or feature.

Remedied by: Taking countermeasures to prevent premature, irregular cooling and solidification of the material. These can include increasing the injection rate and pressure, increasing the temperature of the mold (to keep the material in liquid form for a longer period of time), and increasing the injection temperature of the nozzle (and thus the material). When permitted by design requirements, increasing the width or diameter of narrow features, and rounding corners, can facilitate a more uniform flow rate and cooling time.

2. Short Shot and Short Molding

Caused by: Material cooling too quickly and blocking portions of the mold from being completely filled; gas or air bubbles preventing the mold from being completely filled.

Symptoms: An incomplete part. In a short shot or short molded part, the mold has not been completely filled with the material, and thus the part has not been fully formed. Short shot pieces will almost always be rejected, creating major cost implications.

Remedied by: Guaranteeing that the mold is totally filled with material. Steps to ensure this might include raising material and mold temperature to confirm flow throughout the entire mold, more viscous materials to better facilitate flow, and improved venting features in the mold to allow air to escape. Mold maintenance, like regular vent cleaning and clearing, may also help prevent short shot and short molding.

3. Burn Marks

Caused by: Overheating of the material, due to excessive temperatures of trapped air, the mold, or the nozzle and injection temperature.

Symptoms: A “rusty” or, in extreme cases, blackened appearance on the part, typically near the edges.

Remedied by: Several methods can remedy burn marks, especially if they are occurring frequently or on pieces where aesthetics are important, such as consumer products. These methods include:

- • Lowering the injection speed so that the mold and material cool more uniformly.

- • Lowering the melt temperature of the material so that it takes more time to reach the point of burning.

- • Reducing cycle times so that cooling begins more quickly, both for the material and for any trapped air or gas.

- • Adding or cleaning vents to the mold so that trapped air can escape before heating to the point of burning the material.

Note that burn marks aren’t necessarily detrimental to structural integrity of a piece, and are not automatically cause for part rejection. The integrity of pieces with minor burn marks should be checked, however, to be sure that the material remains intact.

4. Vacuum Voids and Air Pockets

Caused by: Air trapped in the mold cavity, usually on account of two primary factors: irregular cooling and material shrinkage, and insufficient injection pressure.

Symptoms: Small “voids” or air bubbles in the construction of a piece. Voids usually occur near the surface of a piece, but are not always readily apparent, making them more dangerous in cases where they threaten the structural integrity of a piece.

Remedied by: Since vacuum voids due to material shrinkage are most common in thicker areas of a part, and become increasingly likely at higher thicknesses, following a design practice of keeping wall thicknesses below 6 millimeters can be one remedy. In situations where this isn’t possible, moving the gate to the thickest portion of the mold can prevent or attenuate the problem of premature cooling, which is what leads to irregular shrinkage (as still-molten material is pulled outward toward the cooling portion of the material). Alternatively, increasing the injection and holding pressure (and, potentially, the holding time) can help to force air out of the material.

5. Weld Lines

Caused by: Materials meeting in a mold after traveling from two directions (due either to multiple gates or the design of the mold) and cooling at different rates.

Symptoms: Lines or seams on the surface of the piece. Aside from creating aesthetic issues, weld lines occur when portions of the material do not bond properly, and can thus threaten the integrity and quality of the piece.

Remedied by: If the mold or part design can be modified, reformatting the mold to have only one gate or flow path can prevent flow lines. If multiple gates or flow paths are required for the piece, a higher material temperature can help different material flows cool together more uniformly. A higher injection speed can also achieve the same end, ensuring that the material portions reach their meeting point before beginning to cool. Finally, material that is less viscous (in other words, is “thinner” and flows better) can help material from different mold paths bond more easily.

If you’ve had issues with injection molding defects or want to know more about quality assurance on molded parts, contact RevPart today.