Advances and improvements in 3D printing have raised the technology’s profile as a game-changer in manufacturing over the last several years. While rapid prototyping and the additive manufacturing methods that 3D printing comprises have been around in some form for decades, the greater accessibility, affordability and versatility that today’s 3D printing offers mean that its potential to change manufacturing as a whole is at an all-time high.

Yet will 3D printing ever completely replace traditional manufacturing? Will other methods like CNC machining eventually be supplanted by the possibilities that 3D printing offers? In order to uncover the answers to those questions (and others), let’s take a closer look at the benefits that 3D printing offers, and why these questions have been raised in the first place.

Ease of creating complex pieces

Creating complex mechanical constructions via traditional manufacturing has always been difficult, requiring a great amount of precision and skill — even for computer-controlled manufacturing. When tolerances are off even by a few hundredths of an inch (or smaller), it can mean an ineffective part — and lost time, resources, and money for both the manufacturer and the customer. What’s more, assembly of these complex parts is a battle of accuracy and access (in that the area in question to be assembled must be reachable by person or machine).

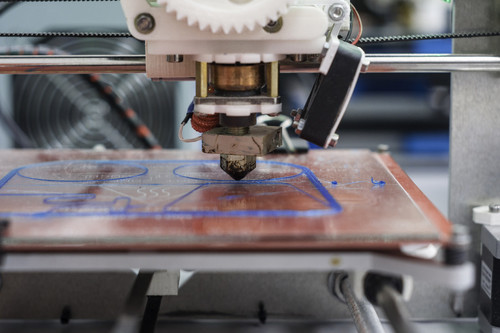

3D printing solves those problems by creating an entire piece in one process through additive manufacturing, simply building a part to spec layer by layer, instead of creating each component and then assembling and finishing the completed product. By integrating the more complex constructions of

a mechanical piece directly into the additive manufacturing process, 3D printing allows a “ready-to-use,” fully assembled part to roll directly off the line.

Much better efficiency in prototyping

Prototypes can be, from a financial standpoint, one of the most inefficient steps in a manufacturing process, although they are also one of the most important steps. However, while manufacturing a prototype may not be cost effective, no manufacturer or customer would think of going to production without testing the manufacturability and quality of a product. Why are prototypes so inefficient, cost-wise? Here are a few reasons:

- • Molds must be built whether you are manufacturing one or 10,000 pieces.

- • Money may be invested into prototypes that never go through to production.

- • Multiple prototypes may need to be built for one product, if design or manufacturability changes are required.

By definition, you never get a direct return on a prototype — prototypes are not intended for sale.

Setup time and cost is required, again, whether you are manufacturing one or 10,000 pieces. What may be efficient for a production run is much less so for a one-off.

A great benefit of 3D printing is that it solves many of these problems. Since pieces can be 3D printed using nothing more than a digital file — instead of requiring a mold to be built or a complete CNC program to be developed — many cost inefficiencies are eliminated. If a prototype requires design changes, the CAD or Solidworks file can simply be modified and another prototype produced in just a few hours, at a negligible monetary cost. Material costs may also be decreased — 3D printing results in much less material waste.

Increased speed to market

As mentioned above, 3D printing can solve many inefficiencies in the prototyping process. These can be inefficiencies not only on the financial front, but also on the time front. The versatility and relative ease with which new prototypes can be modified and created can mean a much quicker end-to-end process from design to production.

This means that even if the actual output time for a 3D printed piece may be longer than, say, a stamped or machined piece, the time savings involved in the processes surrounding the manufacture of the piece more than offset that, especially in cases where multiple iterations of a prototype may be required. Faster time to market means benefits to the bottom line, including a quicker return on investment.

Potential for breakthroughs with materials

Unlike the purely mechanical processes involved in traditional manufacturing — take a raw material and apply the required process to it — 3D printing has the potential to deal with, and possibly manipulate, materials at a more elemental level. The intricacies of the 3D printing process — where materials may be broken down into component forms in order to facilitate the additive nature of the process — holds great potential for modifying the material qualities of a particular metal.

The common thread

One recurring theme runs through each of these examples: it certainly holds great potential to impact manufacturing as we know it, but it’s important to understand the specific cases where the greatest benefits can be seen. 3D printing will change the way prototyping is done, which will in turn affect every step of the production process and might lead to new breakthroughs in the limits of what can be produced.

What is also true, however, is that there are processes for which 3D printing is not as ideal. Long production runs will not be replaced by 3D printing — the time per piece is simply too long when talking about million-piece runs. For one-offs and other short runs, though, 3D printing can and will be the game-changer it’s been touted as.

In short, the greatest potential for 3D printing lies not in replacing traditional manufacturing, but in supplementing it and improving the potential for better overall products. By understanding the benefits and drawbacks of all of the processes available, innovators, product designers and manufacturers will be better able to facilitate advances in their respective fields. While traditional processes like CNC machining aren’t going anywhere, they can be used with greater efficiency — for the processes and projects for which they’re suited best — while efficiencies found in other processes like 3D printing will help lead to a better overall process and product.